A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::open($save_path, $name) should either be compatible with SessionHandlerInterface::open(string $path, string $name): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 132

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::close() should either be compatible with SessionHandlerInterface::close(): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 294

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::read($session_id) should either be compatible with SessionHandlerInterface::read(string $id): string|false, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 168

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::write($session_id, $session_data) should either be compatible with SessionHandlerInterface::write(string $id, string $data): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 237

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::destroy($session_id) should either be compatible with SessionHandlerInterface::destroy(string $id): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 317

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::gc($maxlifetime) should either be compatible with SessionHandlerInterface::gc(int $max_lifetime): int|false, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 358

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 282

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: session_set_cookie_params(): Session cookie parameters cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 294

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 304

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 314

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 315

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 316

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 317

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 375

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: drivers/Session_files_driver.php

Line Number: 108

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: session_set_save_handler(): Session save handler cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 110

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

A PHP Error was encountered

Severity: Warning

Message: session_start(): Session cannot be started after headers have already been sent

Filename: Session/Session.php

Line Number: 143

Backtrace:

File: /home/softhills/softhills.co.in/indiainframart/application/controllers/Dynamic.php

File: /home/softhills/softhills.co.in/indiainframart/index.php

Infrastructure manufacturers, suppliers & buyers business directory - indiainframart.com

description

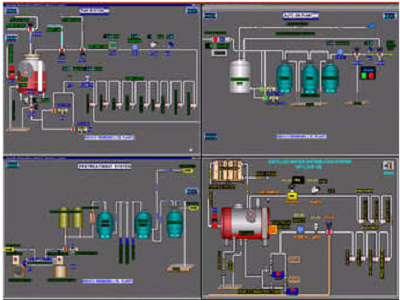

The integration of a human machine interface and programmable logic controller provides a lean automation solution. Manufacturing is a proven, powerful method to boost efficiencies.

Similar concepts and practices that eliminate “waste”-unnecessary equipment and process steps-can be applied to the design, construction, and support of automation systems to enable increased productivity and reliability, yielding increased efficiency. Combining visualization and control means:

Faster machine design by providing an integrated development environment Reduced machine construction costs by eliminating components and wiring Reduced machine support cost and improved operation by centralizing remote access and administration